In Situ Combustion

On this page:

- Schematic

- Introduction

- Other Technology Names

- Description

- Development Status

- Applicability

- Cost

- Duration

- Implementability Considerations

- Resources

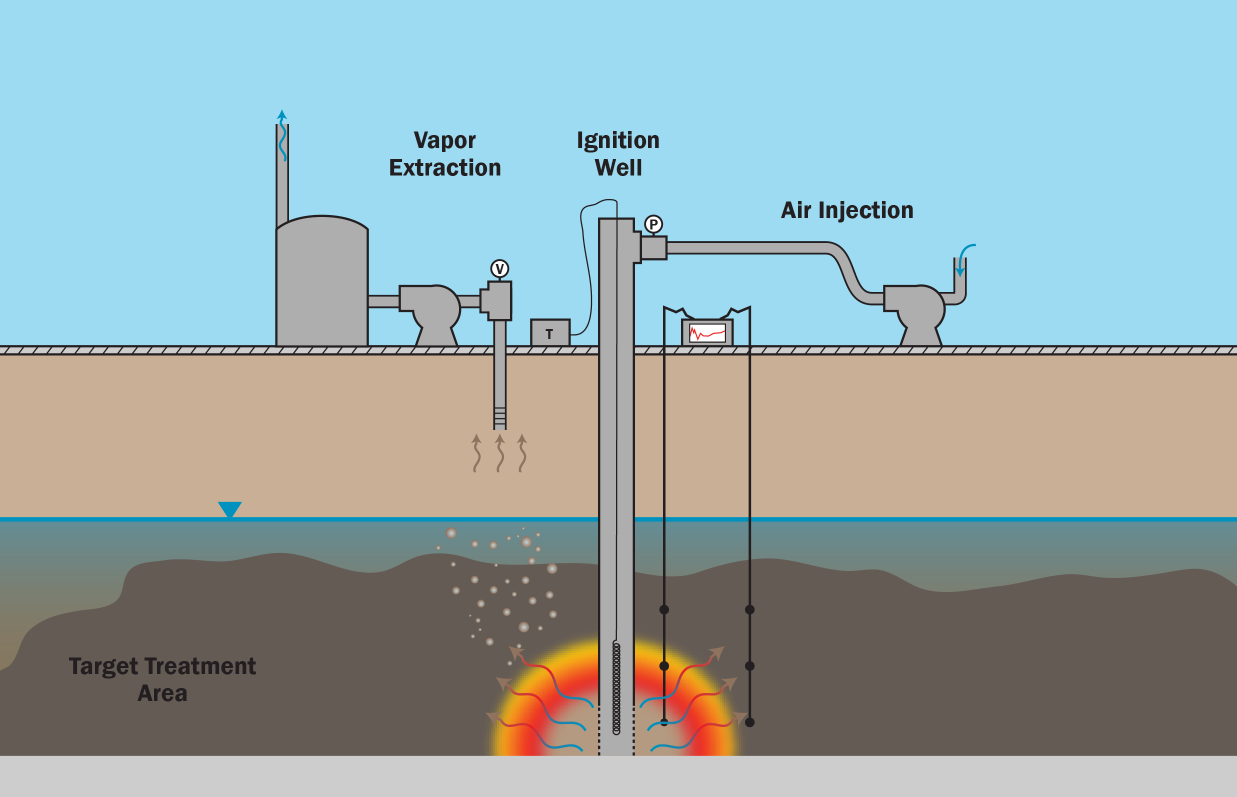

Schematic

Introduction

In situ combustion is an innovative thermal technology based on the principles of smoldering, where the contaminants are the source of fuel. The process is initiated through a short duration, low energy ignition event that is sustained by the introduction of air through a well to the target treatment zone. Once the process is initiated (ignited) in situ, the energy released from contaminant combustion is used to pre-heat and initiate combustion of contaminants in adjacent areas, propagating a combustion front through the contaminated zone in a self-sustaining manner (i.e., no external energy or added fuel input following initial ignition) provided a sufficient flux of air is supplied. Active control of the combustion front is maintained by the air supply. This efficient recycling of energy is made possible by the presence of the porous matrix (i.e., contaminated aquifer) that is being remediated. This technology is well suited for application at sites contaminated with petroleum hydrocarbons including coal tar, creosote, Bunker C fuel, Navy special fuel oil, and other heavy viscous petroleum-based hydrocarbons.

Other Technology Names

Self-Sustaining Treatment for Active Remediation (STAR)

Description

Smoldering is a flameless form of combustion, generating heat from reactions occurring on the surface of a solid or liquid fuel when the fuel is heated in an oxidizing environment. It occurs when the rate of fuel heating is slower than the rate at which the oxidizer diffuses into the fuel. Smoldering can occur only under conditions where the fuel source has a large surface area exposed to the oxidizer. This condition is often attained within a porous matrix where the matrix material has a very large surface-to-volume ratio. For the applications of smoldering for in situ soil remediation, the fuel is a non-aqueous phase liquid (NAPL) and the porous matrix is the impacted soil and aquifer material.

Smoldering combustion requires a short duration energy input and the addition of an oxidant (e.g., oxygen in air) to initiate the reaction. It is an exothermic reaction converting carbon compounds and an oxidant to carbon dioxide, water and energy. The net energy produced can initiate subsequent smoldering reactions, assuming supporting conditions exist, and continue subsequent smoldering in a self-sustaining manner. The heat energy required for the combustion of contaminants primarily comes from the inherent energy within the target contaminants themselves, making it an energy efficient remediation technology. It can achieve a high degree of mass destruction (i.e., > 90%) in situ and very high temperatures (>900 °F) for complete treatment.

Aboveground equipment is similar to that used in air sparging and soil vapor extraction systems. A typical system includes a compressor for sub-surface air delivery, a blower for soil vapor collection, and vapor phase granular activated carbon (GAC) or a thermal oxidizer for vapor treatment. Specialized equipment includes the use of carbon steel ignition wells with a stainless steel screen, removable/reusable in-well heaters to initiate the combustion process, and subsurface multi-level thermocouple bundles to track the combustion front. Equipment can be housed and transported on a portable trailer.

The site generally is divided into small "treatment cells." Each cell includes one or more ignition wells, having a 10 to 20 ft radius of influence as determined by pilot testing. Ignition wells within a given cell may be operated simultaneously, with the construction materials recycled between cells. Additional cells are easily added in the field if the areal extent of the NAPL is found to be greater than anticipated. Cell radius and spacing can be adjusted based on results of application (e.g., soil temperature, measured contaminants of concern [COCs] in vapor, achievable flowrates) of previous cells.

In situ combustion results in permanent removal (mass destruction) of target NAPL and generates little waste. It results in the oxidation of contaminants to create innocuous byproducts. A small percentage of the contaminants are volatilized and captured by vapor recovery wells and an appropriate vapor treatment system. Even if small portions of the site are not directly treated by the smoldering front, heat liberated by the reaction elevates the temperature of the aquifer and can volatilize a portion of those contaminants. A network of wells installed in the vadose zone are used to recover the vapor, which is treated aboveground using GAC or thermal oxidation, prior to being discharged to the atmosphere.

If properly applied, this technology has a minimum impact on receptors. There is little concern for inducing NAPL migration during application since the NAPL is consumed very quickly as the smoldering front propagates through the formation. Furthermore, the flow of air is carefully controlled and monitored to prevent mounding and displacement of NAPL and groundwater during application.

Development Status and Availability

The following checklist provides a summary of the development and implementation status of in situ combustion:

☐ At the laboratory/bench scale and shows promise

☒ In pilot studies

☒ At full scale 1

☐ To remediate an entire site (source in vadose zone)

☒ To remediate a source only

☒ As part of a technology train

☐ As the final remedy at multiple sites

☐ To successfully attain cleanup goals in multiple sites

In situ combustion is available through the following vendors:

☒ Commercially available nationwide

☐ Commercially available through limited vendors because of licensing or specialized equipment

☐ Research organizations and academia

Applicability

|

Contaminant Class Applicability Rating for In Situ Combustion (Rating codes: Demonstrated Effectiveness, ◐ Limited Effectiveness, No Demonstrated Effectiveness, ♢ Level of Effectiveness dependent upon specific contaminant and its application/design, I/D Insufficient Data) |

||||||||

|---|---|---|---|---|---|---|---|---|

Nonhalogenated VOC |

Halogenated VOC |

Nonhalogenated SVOC |

Halogenated SVOC |

Fuels |

Inorganics |

Radionuclides |

Munitions |

Emerging Contaminants |

| ◐ | ◐ | ◐ | ◐ | ● | ○ | ○ | ○ | ○ |

In situ combustion is applicable for treatment of source zones contaminated with viscous NAPLs including creosote, coal tar, and viscous fuels such as Bunker C or Navy special fuel oil. The technology is well suited for sites having a laterally continuous NAPL layer with soil concentrations of at least 3,000 mg/kg of total petroleum hydrocarbon (TPH) contamination. The technology has been demonstrated to treat NAPL present in the capillary fringe as well as in the saturated zone.

This technology is not recommended for sites contaminated with highly volatile fuels such as aviation gasoline (AVGAS) or gasoline since flaming (as opposed to smoldering) combustion may occur, and uncontrollable fire and/or explosion could result. At least one demonstration of the technology to treat trichloroethylene by introducing and combusting emulsified vegetable oil, as a surrogate fuel, has been reported in the literature (Salmon et al., 2015). The added step of having to add a fuel introduces additional uncertainty, risk, and cost into the application of the technology. Application of this technology at sites contaminated with lighter-end fuels such as diesel or JP-5 has not been performed.

In situ combustion will remove semi-volatile organic compounds (SVOCs) and volatile organic compounds (VOCs) to varying degrees. SVOCs and VOCs present in the source area where smoldering occurs will be almost completely removed. However, removal will be less in areas immediately adjacent to the smoldering front where heating, volatilization, and subsequent vapor recovery are performed depending on the specific contaminant and degree of heating/volatilization that occurs.

It is important to first perform inexpensive bench-scale treatability tests followed by a pilot test prior to designing a full-scale system. Bench-scale testing determines parameters such as ignition conditions, soil temperature profiles, and velocity of the smoldering front. The pilot test is then designed using this information and performed to demonstrate the site-specific efficacy of the technology and to collect the parameters necessary for designing full-scale remediation.

Cost

Like all thermal technologies, in situ combustion is a very aggressive NAPL removal technology. The cost to implement it typically is higher compared to other less aggressive technologies, though would have lower costs than other in-situ thermal technologies that have to add energy to the subsurface via electricity or burning hydrocarbons. Similar to other in situ thermal treatment technologies, the most critical cost factors are associated with the nature and extent of contamination (i.e., size of the treatment area), and number of ignition wells and vapor recovery points required. However, if NAPL is contiguous across large areas, fewer ignition wells are required and there is less chance that the combustion reaction terminates due to lack of a fuel source. As with all in situ technologies, application costs vary according to site conditions and contaminants. Major cost drivers include:

Upfront Costs

- Need for pilot studies or bench-scale tests to demonstrate effectiveness at a particular site. Testing is especially important due to the innovative nature of the technology.

- Areal extent and depth of contamination. The size of the treatment area impacts the number of ignition points and recovery wells and capacity of vapor treatment equipment.

- Uniformity and composition of NAPL.

- Radius of influence of ignition wells, which typically ranges between 10 to 20 ft.

- Vapor treatment requirements.

- Site lithology can impact design and application. For instance, if contamination is located in or below an impermeable zone, it may be difficult to adequately distribute air into that zone, resulting in a poor radius of influence.

Operation and Maintenance Costs

- The size of treatment area impacts, which affects treatment timeframe.

- Monitoring requirements after application.

The list above highlights those cost dependencies specific to in situ combustion and does not consider the dependencies that are general to most in situ remediation technologies. Click here for a general discussion on costing which includes definitions and repetitive costs for remediation technologies. A project-specific cost estimate can be obtained using an integrated cost-estimating application such as RACER® or consulting with a subject matter expert.

Duration

Full-scale implementation can typically run between a few months to several years depending on the areal extent of contamination. The technology typically is applied by grouping ignition wells into cells. Multiple cells may be ignited to provide simultaneous treatment in two or more areas. In general, it can take up to 10 days to treat each cell, but can vary somewhat from site to site depending on the propagation velocity of the combustion front. Additional time between treatments is required to remove electrodes and reinstall them in new locations. Downtime between treatments can be minimized by having a sufficient number of additional ignitors available so that ignitors can be installed at one location, while treatment and demobilization (ignitor removal and well abandonment) are performed in another.

Primary factors that influence the duration of in situ combustion include:

- Areal extent of NAPL

- Number of treatment cells simultaneously operated.

- Smoldering front propagation velocity (as determined by pilot test)

Implementability Considerations

The following are key considerations associated with applying in situ combustion:

- Nature of NAPL. The technology may not be implemented at sites contaminated with lighter end petroleum hydrocarbons such as gasoline, aviation gasoline, JP-4 jet fuel, etc.

- In situ combustion is not impacted by high groundwater flow since the injected air creates a flow away from the injection well. However, high hydraulic conductivity resulting from large void spaces (e.g. karst material) can inhibit propagation of the combustion reaction.

- Impermeable lithology, such as glacial till, will inhibit the distribution of air into the aquifer.

- Subsidence can occur if lithology contains high levels of organic material (e.g., peat) that is readily oxidized.

- Clay lenses will impede vertical air flow.

- May be less effective at areas of non-continuous NAPL and/or thin intervals of NAPL saturated soil.

- Difficult to apply when concentrations of TPH in soil are less than 3,000 mg/kg.

- Compatibility and preponderance of utilities, wells, and other subsurface artifacts.

- Energy requirements tend to be minimal in comparison to other thermal treatment technologies. Power must be supplied to each ignition well, soil vapor recovery blower, and controls. Power is not required at the ignition wells after the combustion has been initiated.

- NAPL is destroyed in situ and cannot be recycled.

Resources

American Academy of Environmental Engineers and Scientists (AAEES). The Evolution of STAR from Laboratory Concept to Full-Scale In Situ Implementation (2017).

Discusses application of STAR from bench scale through implementation of full scale to treat coal tar at a site located in New Jersey.

Salman, Madiha, J.I Gerhard, D.W. Major, P. Pironi, R. Hadden. Remediation of Trichloroethylene-Contaminated Soils by STAR Technology using Vegetable Oil Smoldering (2015)

Journal of Hazardous Materials

Describes results of a demonstration using STAR in conjunction with emulsified vegetable oil to treat trichloroethylene.

Scholes, G.C., J.I. Gerhard, G.P. Grant, D.W. Major, J.E. Vidumsky, C. Switzer, J.L. Torero. Smoldering Remediation of Coal-Tar-Contaminated Soil: Pilot Field Tests of STAR (2015)

Environmental Science and Technology

Describes results of an in situ pilot test using STAR to treat coal tar and provides pertinent design data.

Switzer, C., P. Pironi, J.I. Gerhard, G. Rein, J.L. Torero. Self-Sustaining Smoldering Combustion: A Novel Remediation Process for Non-Aqueous-Phase Liquids in Porous Media (2014)

Environmental Science and Technology

Describes results of 23 bench-scale experiments that demonstrate the efficacy of STAR to treat heavy-end petroleum hydrocarbon contamination.

At present, in situ combustion predominantly has been used in pilot-scale studies. However, limited full-scale application has been documented (AAEES, 2017) ↩

At present, in situ combustion predominantly has been used in pilot-scale studies. However, limited full-scale application has been documented (AAEES, 2017) ↩