Biopiles

On this page:

- Schematic

- Introduction

- Other Technology Names

- Description

- Development Status

- Applicability

- Cost

- Duration

- Implementability Considerations

- Resources

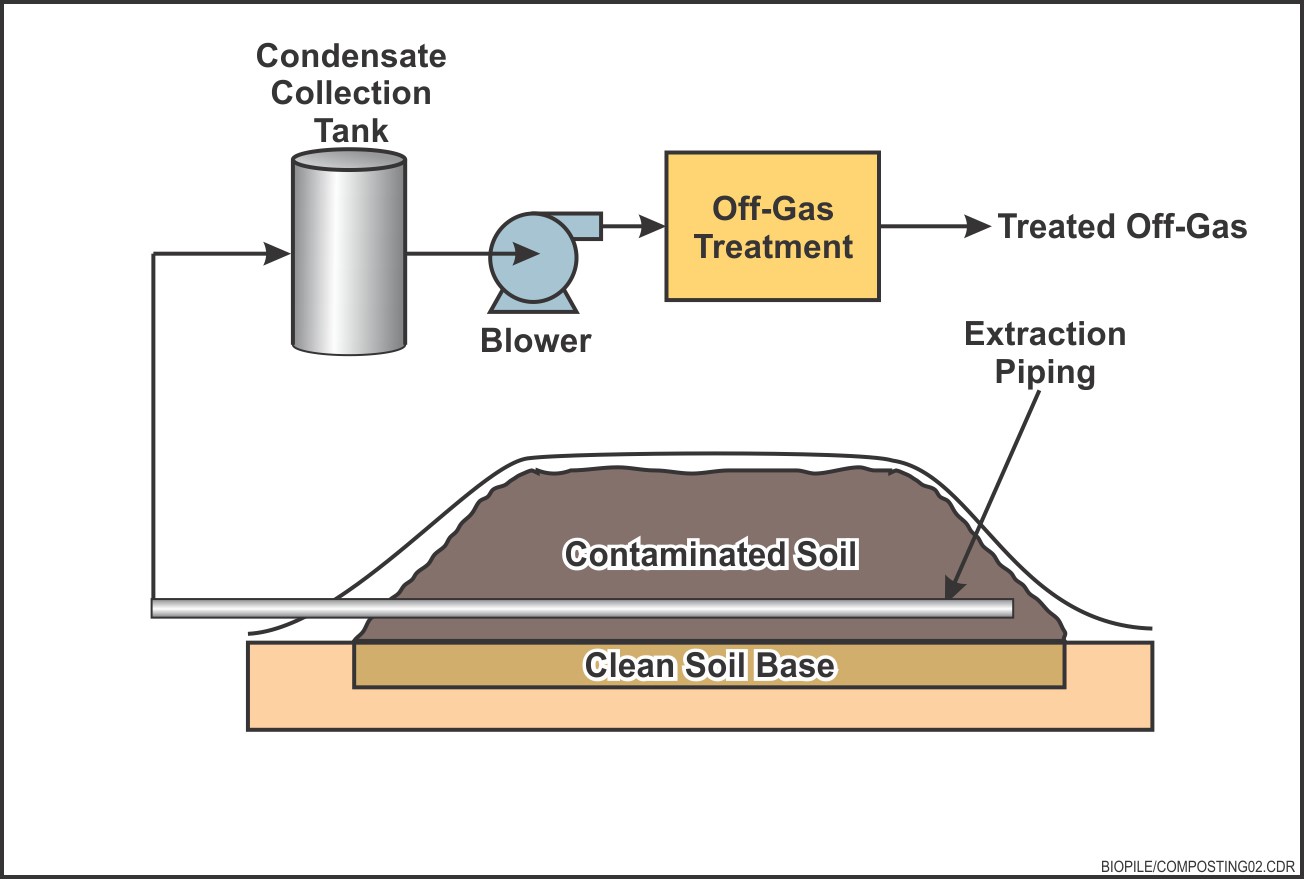

Schematic

This information may be reproduced without restriction as long as the source attribution is included.

Biopile System Schematic

Introduction

A biopile is an ex situ treatment technology that leverages biological processes to convert contaminants to low-toxicity byproducts. Excavated soil or sediment is placed in piles onto an impermeable base or pad equipped with aeration to optimize and control the rate of biodegradation. Pads typically are constructed with a cover and adequate drainage to manage exposure to precipitation and with probes to monitor temperature, moisture content, and contaminant concentrations. Optional equipment can include a moisture addition system, leachate collection system, and off-gas treatment based on site-specific properties and regulatory requirements (NFESC, 1996).

Other Technology Names

Bioheaps

Biomounds

Heap pile bioremediation

Biocells

Description

Contaminated soil is excavated and placed into localized piles and aerated to stimulate microbial activity to aerobically degrade the contaminants. A biopile is designed and operated to provide optimum temperature, moisture content, aeration, and nutrient conditions to promote rapid biodegradation. In most cases, degradation is achieved by indigenous microorganisms; however, the contaminated soils can be bioaugmented if necessary. A biopile typically is operated so that the pile material temperature rises because of heat produced by the biodegradation process and the higher temperature increases the degradation rate. Biopiles are similar to composting in that amendments may be added to facilitate degradation. However, biopiles are not designed to achieve the high thermophilic temperatures (>50 °C) that are required for composting. Key biopile design considerations include:

- Dimensions. Biopiles typically are designed to be between 3 and 10 ft high (H). The length (L) and width (W) of the pile are unlimited; however, the overall size (L/W/H) is often determined by the equipment used to construct the pile and space availability.

- Foundation. Biopiles typically are constructed with an impermeable base to prevent contaminated groundwater and/or leached contaminants from being released back into the environment beneath the pile. Liquid barriers may be as simple as plastic sheets placed over the ground surface or as sophisticated as a permanent concrete pad depending on the mass of soil expected to be treated.

- Moisture Content. Water should be added periodically to maintain a moisture content between 40 to 85 percent of field capacity (EPA, 1995) to provide a suitable environment for biodegradation to occur. Water can be added to the top of the pile using sprays or drip irrigation systems. Moisture should not be so high that it completely fills the pore space and impedes air movement and distribution. If excess water is expected, the biopile can be designed with a drainage (and treatment) system to collect, treat, and discharge the water.

- Soil Properties. The material within the biopile should have good structure and porosity to provide a high percentage of voids, allowing efficient air movement. Bulking agents, such as straw, bark or wood chips, can be added during construction to increase permeability. A soil nutrient analysis can be performed and an amendment, such as fertilizer, can be added as needed to provide an optimum balance of carbon, nitrogen, and phosphorous (generally 100:10:1 to 100:10:0.5 [EPA, 2016]). Alternatively, an optimum ratio of nitrogen and phosphorous may be determined based on an analysis of the concentration of total petroleum hydrocarbons (TPH) in the soil. Fertilizer can be added easily at routine intervals by dissolving the fertilizer in water and distributing it using the watering system. In addition, it is desirable to maintain a soil pH between 6 and 8, which is necessary for optimum microbial activity and biodegradation to occur. Buffering agents and other amendments (e.g., line and sulfur) can be added as necessary to maintain the pH within this range.

- Aeration. Either passive or forced air aeration may be utilized. Passive systems employ perforated tubing or slotted pipes placed at various heights throughout the pile with their ends protruding outside of the pile to allow air exchange. Wind-driven, passive turbine vents may also be attached to the protruding ends of the ventilation piping. Active aeration consists of using a blower to move air through a network of slotted pipe placed at one or more depths to allow for proper aeration of the entire pile. Air may be extracted under vacuum or injected under pressure. Vapor treatment of the air stream may be required since it may contain high levels of contaminants, and a knockout system should be used to prevent water from entering and damaging the blowers. Despite the lower cost for passive aeration systems, active aeration is preferred, because it gives more complete and more controllable air flow that speeds bioremediation in the pile (NFESC, 1996).

- Cover. An impermeable (plastic) cover may need to be placed over the biopile depending on climatic conditions at the site. A cover should be used at locations where excessive rain is expected to reduce leaching of contaminants from the biopile. In cold climates, a cover may be used to retain heat within the pile.

Development Status and Availability

The following checklist provides a summary of the development and implementation status of biopiles:

☐ At the laboratory/bench scale and shows promise

☐ In pilot studies

☒ At full scale

☐ To remediate an entire site (source and plume)

☒ To remediate a source only

☒ As part of a technology train

☐ As the final remedy at multiple sites

☒ To successfully attain cleanup goals in multiple sites

Biopiles are available through the following vendors:

☒ Commercially available nationwide

☐ Commercially available through limited vendors because of licensing or specialized equipment

☐ Research organizations and academia

Applicability

|

Contaminant Class Applicability Rating for Biopiles (Rating codes: Demonstrated Effectiveness, ◐ Limited Effectiveness, No Demonstrated Effectiveness, ♢ Level of Effectiveness dependent upon specific contaminant and its application/design, I/D Insufficient Data) | ||||||||

|---|---|---|---|---|---|---|---|---|

Nonhalogenated VOC |

Halogenated VOC |

Nonhalogenated SVOC |

Halogenated SVOC |

Fuels |

Inorganics |

Radionuclides |

Munitions |

Emerging Contaminants |

| ● | ◐ | ● | ◐ | ● | ○ | ○ | ◐ | I/D |

Biopiles are used to treat aerobically biodegradable organic compounds such as nonhalogenated volatile organic compounds (VOCs) and semivolatile organic compounds (SVOCs). Biopiles are used frequently to treat soils contaminated with petroleum hydrocarbons. The lighter petroleum products tend to evaporate from the pile due to aeration, but the medium and heavy petroleum hydrocarbons are degraded aerobically. Effectiveness is varied for halogenated VOCs, SVOCs and pesticides, where halogenated VOCs may be stripped from the biopile due to volatilization as opposed to aerobic degradation. Less frequently, low levels of explosive residues, such as trinitrotoluene (TNT) or Royal Demolition Explosive (RDX), also can be treated. Biopiles are not effective at removing inorganic contaminants and radionuclides.

Cost

Biopiles are a moderate cost technology used to treat soils that have been excavated and require treatment. Cost can be high if a permanent facility is required or if large volumes of soil must be treated. Operation requires minimal maintenance and monitoring, and energy requirements tend to be low. When considering using a biopile as an alternative to an in situ technology or other type of ex situ treatment, consideration must be given to the cost to excavate and transport the soil to the biopile and transport the treated soil to its final destination. These activities and associated costs are ancillary to the construction and operation cost of the biopile itself and are therefore not considered here. Major cost drivers include:

Upfront Costs

- Sampling and analysis. Samples of stockpiled soil/sediment should be analyzed to determine the starting concentrations of the contaminants and the need for amendments (nutrients, water, bulking agents, etc.). These analyses are typically relatively low cost.

- Procuring and preparing the necessary space for construction and installation of the biopiles.

- Treatability testing. Bench-scale testing should be performed to determine ability to achieve remedial goals and associated timeframe.

- Equipment. Capital equipment required includes a blower, liquid knockout equipment, any necessary vapor treatment equipment, and plumbing for the aeration system.

- Construction. Construction of a biopile can use a relatively simple design for a temporary system to treat a small amount of material or a complex, permanent design for long-term operation. A biopile might simply consist of a bermed plastic liner placed over the ground with drainage tile used for aeration, which would be low cost. A semi-permanent or permanent system may include a more costly concrete pad with trenches used for fluid collection/drainage and for placement of aeration piping.

- Soil volume. The volume of soil requiring treatment and associated size and number of pads. Heavy machinery is required to construct the pile.

- Emission controls. The need for vapor treatment can substantially increase cost depending on the type of treatment (e.g., granular activated carbon [GAC], oxidation) that may be required.

Operation and Maintenance Costs

- Labor. Labor to operate and maintain biopiles is generally minimal so costs are often low. Biopiles are relatively simplistic and do not require much monitoring and maintenance once they have been constructed.

- Utilities. Utility costs including water and electricity are generally low.

- Sampling and analysis. Cost for sampling and analysis, including performance monitoring and confirmatory analyses of soil, are dependent on volume of soil treated and specific sampling and analysis requirements.

- Emission controls. Vapor treatment may be required. Most often GAC is sufficient and costs for replacement and regeneration and sampling and analysis would be incurred. If more aggressive treatment, such as oxidation, is required, electric, gas, and rental costs would be incurred. Costs for off-gas treatment can also be minimized by regulating the air flow (and volatilization) rate through the pile.

- Runoff management. Treatment and/or disposal of effluent/runoff water may be required depending on the contaminant levels in the discharge water. Disposal cost for water may be minimized by maintaining appropriate moisture levels in the pile to induce biodegradation but prevent saturation. Costs for disposal should be relatively low under proper operating conditions.

- Nutrient addition. Treatability testing can be used to determine the necessity and frequency of nutrient addition.

- Soil disposal. Treated soil must be disposed on site or transported and disposed off site. Disposal location, transportation distance, and any permitting fees impact cost. If remediation goals are not met, soil may need to be disposed of as hazardous waste (refer to 40 CFR 261 for applicable criteria).

The list above highlights those cost dependencies specific to biopiles and does not consider the dependencies that are general to most remediation technologies. Click here for a general discussion on costing which includes definitions and repetitive costs for remediation technologies. A project-specific cost estimate can be obtained using an integrated cost-estimating application such as RACER® or consulting with a subject matter expert.

Duration

Biopiles are a short-term remediation technology. Typical operating durations are four to six months per batch of contaminated soil. Duration is highly dependent on the biodegradation rate. Soils contaminated with shorter-chain, more easily biodegradable petroleum hydrocarbons (e.g., gasoline) are treated faster than those containing long-chained polycyclic aromatic hydrocarbons. The starting concentration of contaminants also influences the time required to achieve remedial goals. In some cases, concentrations may be too high for biodegradation to proceed and must be diluted by mixing in clean material, which reduces the volume of contaminated soil that can be treated in a batch for a given size of treatment facility.

Implementability Considerations

The following are key considerations for the application of biopiles:

- Very high contaminant concentrations may be toxic to microorganisms. Clean soil can be added to dilute concentrations.

- Substantial space may be required for biopile construction and operation, but generally is less than that required for alternative ex situ technologies such as composting or landfarming.

- Low ambient temperatures can decrease biodegradation rates.

- Bulking agents may be required for clay-rich soils and may increase the volume of the pile.

- Heavy metals are not treated by this method and can be toxic to microorganisms.

- Air pollution controls may be needed to reduce emissions of volatile compounds from the biopile.

- Prior to full-scale implementation, treatability studies are recommended.

Resources

EPA. How to Evaluate Alternative Cleanup Technologies for Underground Storage Tank Sites: A Guide for Corrective Action Plan Reviewers: Chapter 4 Biopiles (2017)

A manual on cleanup options for petroleum hydrocarbons including biopile application, operation principles, system design, advantages and disadvantages.

NAVFAC. Biopile Design and Construction Manual (1996)

This manual provides details on selection procedures and design and construction steps for implementing the biopile technology for ex situ treatment of soils contaminated with petroleum hydrocarbons.

NAVFAC. Biopile Operation and Maintenance Manual (1996)

The manual was created to support biopile work conducted at U.S. Navy and Marine Corps facilities and is a companion document to the site-specific biopile design and construction report that usually will be prepared upon completion of biopile construction at each site.

Weston. Remediation of Diesel and Fuel Hydrocarbons in High Clay Content Soils (March 2000)

Remediation of diesel and fuel oil hydrocarbons in high clay content soils, a field comparison of amendment performance conducted at Mare Island Naval Shipyard.