Composting

On this page:

- Schematic

- Introduction

- Other Technology Names

- Description

- Development Status

- Applicability

- Cost

- Duration

- Implementability Considerations

- Resources

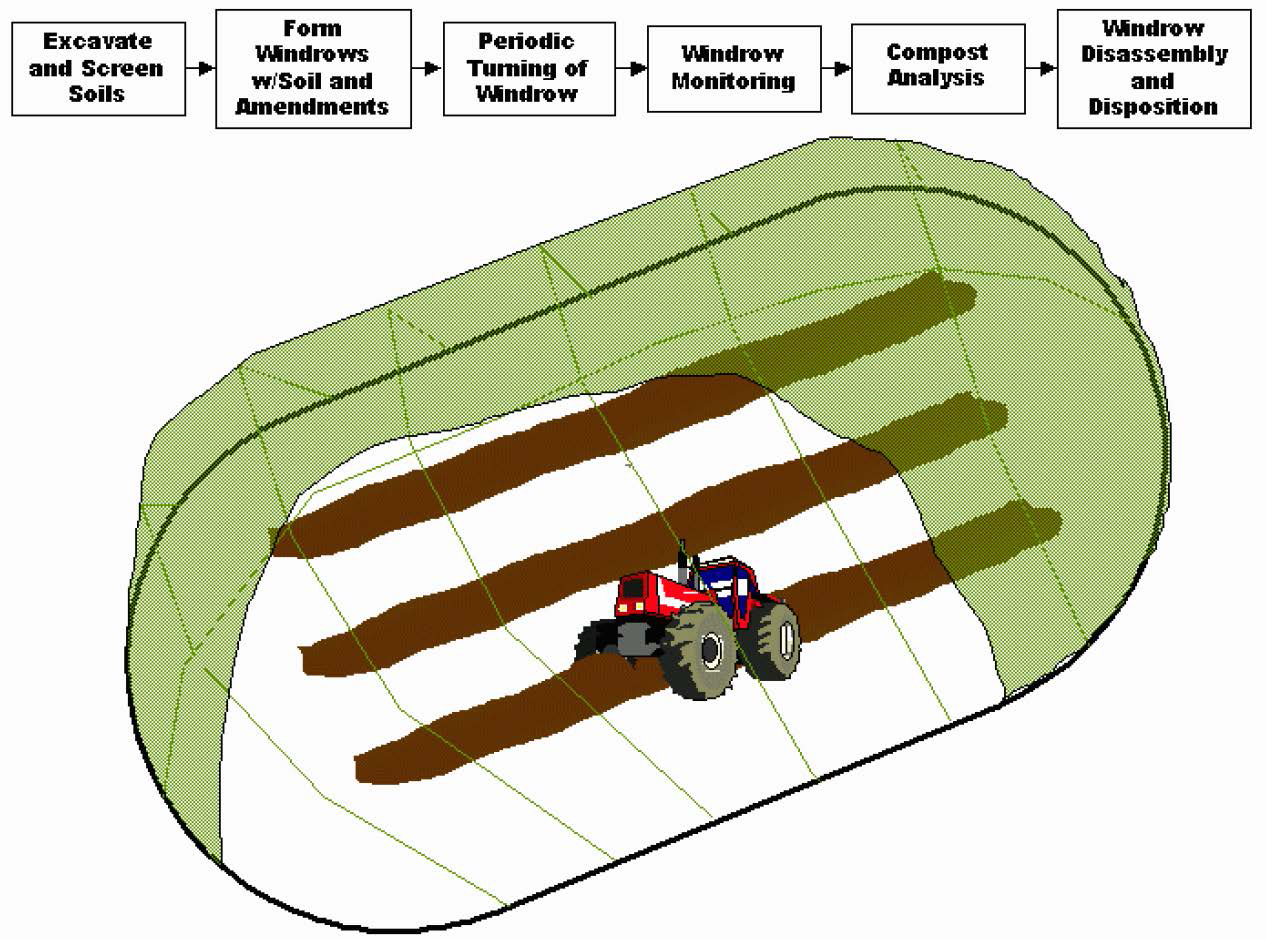

Schematic

This information may be reproduced without restriction as long as the source attribution is included.

Windrow Composting Schematic

Introduction

Composting is used to treat excavated soils and dredged sediments contaminated with a variety of pollutants. The contaminated media is mixed with bulking agents and organic amendments such as mature compost, wood chips, hay, manure, and vegetative (e.g., potato) wastes. Composting differs from technologies such as biopiles and landfarming in that a sufficient quantity of organic material is added to maintain thermophilic temperatures during the degradation process. Proper amendment selection ensures adequate porosity and aeration and provides a balance of carbon and nitrogen to promote microbial activity. Although composting can rely on natural aeration, many times it is enhanced by the design of the compost piles, including mechanical mixing or the introduction of air using blowers.

Other Technology Names

Bioheaps

Biomounds

Heap pile bioremediation

Biocells

Description

Composting is a controlled biological process by which organic contaminants, such as petroleum hydrocarbons, in soil or sediment are converted by microorganisms to innocuous byproducts. Composting is designed to attain thermophilic conditions (at least 50°C) to facilitate biodegradation of the contaminants. The increased temperature results from heat produced by microorganisms during degradation of the organic material in the waste and serves to accelerate the rate of biodegradation. In most cases, biodegradation is performed by indigenous microorganisms, but media can be bioaugmented with non-indigenous organisms.

Soils are excavated and mixed with bulking agents and organic amendments, such as wood chips, animal, and vegetative wastes or mature compost, to enhance the porosity of the mixture to be decomposed and provide the organic material required to maintain thermophilic temperatures. Factors that affect degradation efficiency are the ability to achieve adequate aeration and maintain a suitable moisture content (about 40 to 60 percent) during the degradation process. Maximum degradation efficiency typically is achieved through aeration by methods such as mechanical mixing (e.g., windrow turning) or convection of air using blowers. If necessary, irrigation can be performed to ensure a sufficient moisture content. Composting is commonly applied using one of three types of designs:

- Aerated static piles, where compost is formed into piles and aerated with blowers or vacuum pumps as needed to maintain an aerobic environment for biodegradation to occur. This design is similar to a biopile; however, it is differentiated by the requirement to maintain thermophilic temperatures, which require a much higher percentage of amended material (e.g., mature compost to be blended with the soil or sediment). Many times, covers are placed over the piles to help maintain the design reaction temperature.

- Mechanically agitated in-vessel composting where soil or sediment is placed in a reactor vessel along with necessary organic amendments and continuously mixed and aerated. This method is more commonly used to treat municipal wastes where odors can be problematic and less commonly used to treat contaminated soils and sediment.

- Windrow composting where materials are placed in long piles known as windrows and periodically mixed with mobile equipment. This is a preferred method because of its simplicity and associated low costs.

All three process designs may be used in the process of treating a single "batch" of contaminated soil or sediment. Windrow composting is usually considered to be the most cost-effective composting alternative. However, it can also have the highest fugitive emissions. If volatile organic compounds (VOCs) or semi-volatile organic compounds (SVOCs) are present in the treated media, an aerated static pile with vapor treatment may be needed to control off-gas emissions. Certain types of amendments can also create other emissions problems (e.g., use of chicken manure may lead to excessive ammonia emissions).

Regardless of the method used, the mechanism by which composting occurs is the same. Initially, high microbial activity and heat production cause temperatures within the compostable material to rise rapidly to a thermophilic temperature of at least 50°C (EPA, 1998). The temperature is maintained by mixing the material and ensuring adequate aeration. After the easily degradable contaminants and other organic constituents are consumed, the temperature and biodegradation rates decrease. Often times, it is necessary to add additional mature compost, which is high in nutrients, bacteria, and fungi, to help ensure thermophilic temperatures are maintained and biodegradation occurs at the expected rate and to completion so that remedial goals are achieved. Because a large fraction of organic material is added to the soil or sediment, the volume of contaminated material increases. If remedial goals are not achieved, a greater volume of waste must be treated by an alternative method and/or properly disposed. It also may be necessary to add water to maintain a moisture content of 50 and 70 percent, which is recommended to maintain microbial activity (EPA, 1998). Temperatures, moisture and change in concentrations of contaminants of concern are monitored at various locations within the material and adjustments to air flow, moisture, and mixing are performed as necessary to maintain design conditions until remedial goals are achieved.

Development Status and Availability

The following checklist provides a summary of the development and implementation status of the composting technology:

☐At the laboratory/bench scale and shows promise

☐In pilot studies

☒At full scale

☐To remediate an entire site (source and plume)

☒To remediate a source only

☐As part of a technology train

☐As the final remedy at multiple sites

☒To successfully attain cleanup goals in multiple sites

Composting systems are available through the following vendors:

☒Commercially available nationwide

☐Commercially available through limited vendors because of licensing or specialized equipment

☐Research organizations and academia

Applicability

|

Contaminant Class Applicability Rating for Composting (Rating codes: Demonstrated Effectiveness, ◐ Limited Effectiveness, No Demonstrated Effectiveness, I/D Insufficient Data, N/A Not Applicable) | ||||||||

|---|---|---|---|---|---|---|---|---|

Nonhalogenated VOC |

Halogenated VOC |

Nonhalogenated SVOC |

Halogenated SVOC |

Fuels |

Inorganics |

Radionuclides |

Munitions |

Emerging Contaminants |

| ● | ◐ | ● | ◐ | ● | ○ | ○ | ◐ | I/D |

Composting has a long history of being applied to treat organic materials, such as manure and municipal wastes. In the last few decades, it has been used to treat soils and sediments contaminated with petroleum hydrocarbons and aerobically biodegradable organic compounds such as nonhalogenated VOCs and SVOCs (EPA, 1998). It has shown effective results in bench-scale to large pilot-scale tests as well as some full-scale projects to treat solvents, pesticides, and explosive compounds including trinitrotouluene (TNT), hexahydro-1,3,5-trinitro-1,3,5-triazine (RDX) (EPA, 1998; Williams et al., 1991), and ammonium picrate. Studies have found that blends containing 40 to 70 percent mature compost are effective at achieving degradation of difficult to degrade compounds such as TNT and RDX (EPA, 1998). Composting has also been shown to be applicable for treatment of some pesticide and herbicide-contaminated soils (Lui and Cole, 1996).

Composting is most effective at sites contaminated with mid-range petroleum hydrocarbons. Aerobic, thermophilic composting is also applicable to polycyclic aromatic hydrocarbon (PAH)-contaminated soil. It should be noted that light-end petroleum hydrocarbons may volatilize, especially if air is pulled through the compost piles, and heavier-end compounds (oils and greases) may take a moderate amount of time to completely convert to non-hazardous compounds or be mineralized.

Some chlorophenols, including 2-chlorophenol and 2,4-dichlorophenol, show promise of degradation with composting techniques (EPA, 1998). However, the studies indicate that while degradation and loss of the chlorophenols was relatively rapid, complete degradation or mineralization is limited. More recently, research has identified a number of microorganisms and associated aerobic pathways for the degradation of mono and polychlorophenols, although the ability to biodegrade the polychlorophenols decreases as the number of chlorine atoms increase (Pankaj & Bae, 2014). More highly chlorinated compounds (such as polychlorinated biphenyls [PCBs]) exhibit relatively poor degradation with composting.

Effectiveness is varied for halogenated VOCs, SVOCs and pesticides, where halogenated VOCs may be stripped from the compost systems due to volatilization as opposed to aerobic degradation. However, halogenated VOCs and SVOCs may be degraded under anaerobic conditions (EPA, 1998), and special attention to the conditions of the compost pile is needed to degrade these compounds.

Cost

Composting is a low to moderate cost technology to treat soils or sediments that have been excavated and require treatment. Cost will be greater if a permanent facility is required or if large volumes of material must be treated. Operation requires minimal maintenance and monitoring and energy requirements tend to be low. When considering using composting as an alternative to an in situ technology or other types of ex situ disposal, consideration must be given to the cost to excavate and transport the soil to the compost facility and transport the treated material to its final destination. These activities and associated costs are ancillary to the construction and operation cost of composting itself and are therefore not considered here. Major cost drivers include:

Upfront Costs

- Sampling and analysis. Samples of the stockpiled soil/sediment need to be collected and analyzed to determine the starting concentrations of the contaminants and the need for amendments (nutrients, water, bulking agents, etc.).

- Treatability testing. Bench-scale testing should be performed to determine the timeframe for remediation and the potential to achieve remedial goals.

- Treatment Pad / Staging Area. A large aerial footprint is required for stockpiling contaminated soil, storage of amendments, and the area for composting. The aerial footprint is impacted by volume of soil to be treated.

- Equipment. Capital equipment costs for static pile and windrow composting are generally low where only simple equipment (i.e., blower, vapor treatment, and aeration plumbing) is needed. However, if a very uniform and thorough degree of treatment is desired, then a more expensive, specialized, high revolution per minute (RPM) windrow turner may be required. Also, the capacity of the windrow turner (cubic yards per hour) needs to be taken into account, especially for projects where large volumes of soil must be treated. In-vessel composting requires manufactured equipment (vessels) that tends to be relatively expensive. Heavy construction machinery may be needed to lay out the pile or windrows. In-vessel composting systems also may need heavier machinery to load, but the volume of each batch of material treated with a vessel composting system is smaller than the volumes placed in piles or windrows.

- Construction. In rainy climates, composting may have to be performed under a temporary weather cover, or inside of a large building or warehouse. Construction and/or leasing of the weather cover or building can represent a substantial portion of the upfront costs. Alternatively, membrane liners and covers also can be used. Leachate collection systems also may be required depending on the nature of the contaminants, location of composting facility, and local regulatory requirements.

- Emission controls. Vapor treatment may be required depending on the composting method employed and the type of contaminants being treated.

- If animal waste is used as a composting amendment, pathogens and/or low levels of other contaminants (e.g., antibiotics) could be present and might need to be monitored.

Operation and Maintenance Costs

- Labor. Windrow and pile composting systems are relatively simplistic and do not require much labor and equipment once they have been constructed. Labor may be required to mix the treated media and for compost monitoring (e.g., to ensure adequate aeration, moisture content, and temperature). In-vessel composting systems may have greater operation and maintenance requirements, and therefore operation and maintenance costs may be higher.

- Utilities. Electric cost is expected to be low; however, some in-vessel systems may require electricity to rotate the vessel and mix the compost materials. Also, electrical power would be needed for pile compost systems that require blowers.

- Sampling and analysis. Confirmatory sampling and analysis of the soil or sediment likely will be required. Costs are dependent on the number of samples required, which is based on regulatory requirements and volume of media treated.

- Emission controls. If granular activated carbon (GAC) is used to treat vapor, additional maintenance will be required and the GAC will periodically need to be replaced and regenerated.

- Amendments. Nutrient or amendment additions may be needed periodically throughout the process.

- Soil disposal. Treated soil must be disposed on site or transported and disposed off site. Disposal location, transportation distance, and any permitting fees impact cost. If remediation goals are not met, soil may need to be disposed of as hazardous waste (refer to 40 CFR 261 for applicable criteria).

The list above highlights those cost dependencies specific to composting and does not consider the dependencies that are general to most remediation technologies. Click here for a general discussion on costing which includes definitions and repetitive costs for remediation technologies. A project-specific cost estimate can be obtained using an integrated cost-estimating application such as RACER® or consulting with a subject matter expert.

Duration

The duration of treatment for each batch of soil or sediment is expected to be short term (several weeks to months) due to the high biodegradation rates that can be achieved at thermophilic temperatures. However, treatment times can be longer for certain types of contaminants such as long-chain oils and greases that are difficult to biodegrade. In addition, if the resulting compost will be applied as a soil amendment, then an additional curing time of several months will be required to degrade a large fraction of organic matter present, without which the amended compost could drive the soil anaerobic and kill existing vegetation.

The type and design of a compost system has an impact on treatment duration. In-vessel systems provide more controlled environments and can significantly reduce treatment times. In-vessel systems may treat contaminated media in less than a month if sufficient temperature, aeration, and moisture levels are achieved and the contaminants are amenable to biodegradation. However, in-vessel systems typically can only treat relatively small volumes of contaminated soil per batch. Typical operating durations for windrow and pile compost systems are 3 to 6 months per batch of contaminated soil.

Implementability Considerations

The following are key considerations for the application of composting:

- Very high contaminant concentrations may be toxic to microorganisms; however, the addition of mature compost material or other amendments may be used to reduce the contaminant concentrations to non-toxic levels. For instance, laboratory studies that evaluated the degradation of RDX and TNT found that 30 percent soil mixed with 70 percent compost provided the best results (EPA, 1998).

- Application increases the volume of contaminated material due to the amendments that are added. If remedial goals are not achieved, a greater volume of waste must be treated by an alternate method and/or disposed.

- Substantial space may be required for pile or windrow compost construction and operation.

- Low ambient temperatures can decrease biodegradation rates and make it difficult to maintain thermophilic conditions. However, the dimensions of the composting pile can usually be adjusted to accommodate low-temperature conditions (i.e., increasing the pile dimensions for cold climates allows for the interior of the piles to maintain adequate temperature).

- Additional bulking agents may be required for clay-rich soils and may further increase the volume of the pile.

- Heavy metals are not treated by this method and can be toxic to microorganisms.

- If air is pulled through the compost system, air pollution controls may be needed to reduce emissions of volatile compounds from the compost pile.

- Prior to full-scale implementation, treatability studies are recommended.

- Siting of the facility needs to take into account the strong likelihood of objectionable odors. Odor problems may arise due to use of manure, and other organic amendments (e.g., potato waste), especially during the early stage of treatment for each batch. Odors usually begin to subside within the first 2 weeks of blending the amendments into the compost mixture.

Resources

EPA. Cost and Performance Report: Composting Application at the Dubose Oil Products Co. Superfund Site Cantonment, Florida (1995)

This document provides cost and performance data for a composting application at the Dubose Oil Products Co. Superfund site, in Cantonment, Florida.

EPA. Engineering Bulletin: Composting (1996)

This technical bulletin provides an overview of the composting technology.

EPA. An Analysis of Composting as an Environmental Remediation Technology (1998)

This document provides an overview of a variety of ways composting can be used for environmental remediation.

Federal Remediation Technologies Roundtable (FRTR). The Composting Alternative to Incineration of Explosives Contaminated Soils

This Technical Trends webpage summarizes results of two projects using composting to treat TNT- and RDX-contaminated soil.

FRTR. Windrow Composting of Explosives-contaminated Soil at Umatilla Army Depot Activity, Hermiston, Oregon (1992)

This document summarizes the application of composting to treat explosive constituents at the Umatilla Army Depot.

FRTR. Remediation Case Studies: Bioremediation and Vitrification (1997)

This document summarizes two composting studies.

Liu, X and M.A. Cole. Minimum Effective Compost Addition for Remediation of Pesticide-Contaminated Soil (1996). The Science of Composting, Blackie Academic and Professional

This journal article describes the results of a study to determine the volume of mature compost needed to mix with soil to achieve degradation of pesticides.

Arora, Pankaj Kumar Arora and Bae, Hanhong. Bacterial Degradation of Chlorophenols and Their Derivatives (2014). Microbial Cell Factories.

This journal article describes various microorganisms and degradation pathways for chlorophenols.

United States Army Environmental Center (USAEC). Cost and Design for Application of Biotreatment Technologies for Explosives-Contaminated Soils (1997)

This report provides innovative technology demonstration, evaluation and transfer activities for FY 96. The report describes the project, participants, results, and requirements of various ongoing innovative technology projects. Points of contact for additional information are given.

United States Government Publishing Office. Code of Federal Regulations Title 40, Protection of the Environment, Chapter 1, Subchapter 1, Part 261.

Identifies those solid wastes which are subject to regulation as hazardous wastes, and which are subject to the notification requirements of Section 3010 of the Resource Conservation and Recovery Act.

UFGS 02 54 21 Bioremediation of Soils Using Windrow Composting

Provides design and contract guidance for using windrow composting to remediate a range of contaminants of concern.

Williams, R.T., P.S. Ziegenfuss, W.E. Sisk. Composting of Explosives and Propellant Contaminated Soils under Thermophilic and Mesophilic Conditions. Volume 9, Issue 2. (1991). Journal of Industrial Microbiology.

Composting was investigated as a bioremediation technology for clean-up of sediments contaminated with explosives and propellants.